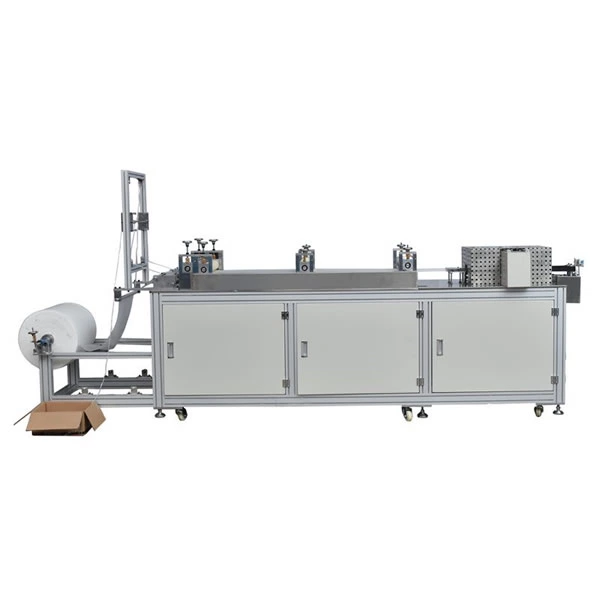

Stainless Steel Paper Straw Machine

Stainless Steel Paper Straw Machine

| Unwinding & Gluing | Cutting System (6 Blades) | Automatic Collecting |

|

|

|

Main Technical Parameter

| Technical Parameter | Control System | ||

| Model | WDF-500SS | Blade | 5 Groups |

| Inner Diameter | 5-10mm | Paper Reel Stand | 6Plies T-bar lPaper Reel Stand |

| Roll Of Paper | 2-3 Plies | Glue System | 3 plies independent glue tank |

| Thickness | 0.25-1mm | Main Motor | 1.5kwx2 CHINA XINLING |

| Cutting Length | 100-820mm | Inverter | 3.7kw CHINA RIHONG |

| Hub Wheel | Two Head | Servo Motor | 0.85kw JAPAN YASKAWA |

| Way Of Fixing Shaft | Clamp | Control System | China |

| Production speed | 10-45m/Min(20-30 degree summer 20-45m/min ,0-10 degree Winter 10-25m/min ) | Linear Guide System | TAIWAN SHANGYIN |

| Way Of Cutting | Circular Cutting Blade | Operator | 1-2 Persons |

| Way Of Gluing | Single / Double Side | Main Part Dimension | 3250*1100*1450mm |

| Type Of Paper Reel Stand | T-bar | Overall Dimension | 7200*4800*1500mm |

| Weight | 1300kgs | Moving Finished Paper Straw | Automatically |

| Way Of Scraping Glue | Independent Glue Box/Polyurethane Scraping Blade | Lubricating Oil | Automatic Giving |

This Machine is suitable for producing different sizes of paper straws,or small paper tube as pen tubes such as 5mm; 6mm; 8mm, 10mm etc.

Feature :

- Adopt human-machine operation interface with PLC controller, main motor is equipped with variable frequency speed regulation, touch screen man-machine interface.Easy for parameters setting & operating.;

- T Bar Paper reeling stand , Slitting rolls are easily placed into reel stand

- Stainless steel gluing box, with polyurethane scraper and high carbon steel plastic knife, durable in use can choose Single or double glue coating unit

- Spiral winding part , specialized operation system , Belt tension device (hand-wheel driven)

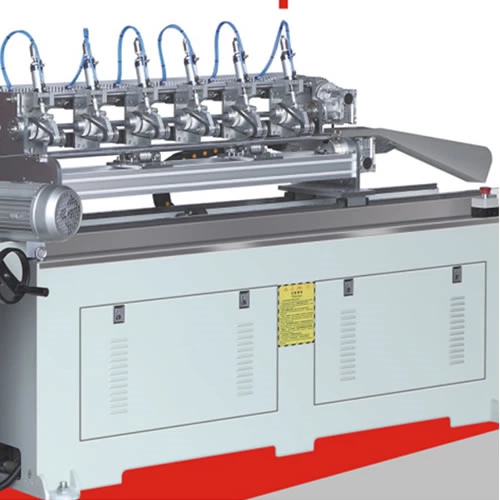

- Round knifes cutting section adopted with numerical multi-blades cutting system.Servo synchronous tracking cutting system makes it higher precision and multi-blades cutting makes it higher efficiency and stable

- Machine body and main spare parts are optional : Full stainless steel or aluminium alloy body instead of painting to Ensure the hygiene and environmental protection of the products.also (FDA medical standard is available )

- Paper tube diameter 5/6 mm, stable production 40 m/min, diameter 8 mm, stable production 35 m/min, diameter 10 mm for bubble tea stable production 30 m/min to be the world’s first.

- Standard advising

European normal standard:196mm

America:210mm/260mm

Structure:60gsm+120gsm+120gsm Wall thickness:0.25-1mm) 3 layers

Factory space requested for machines working totally including 4 machines 5.8m*5.8m

Extra area space need to decided by how much stock you want to put for the materials and paper straws .

Samples: