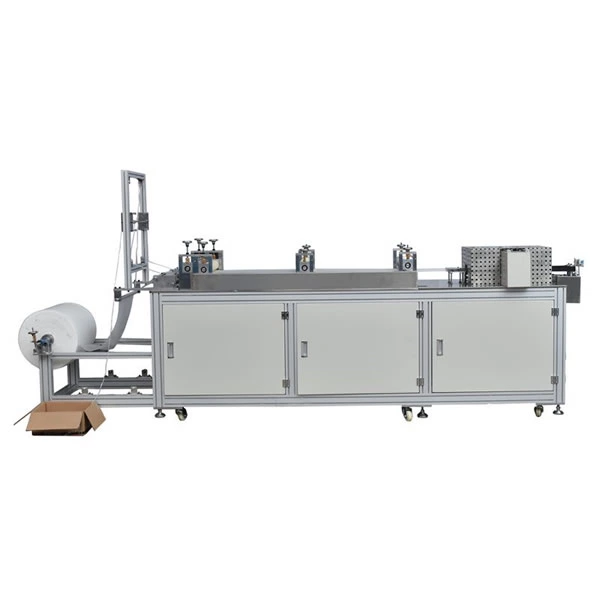

WDF- H22 HIGH SPEED PAPER CUP MACHINE

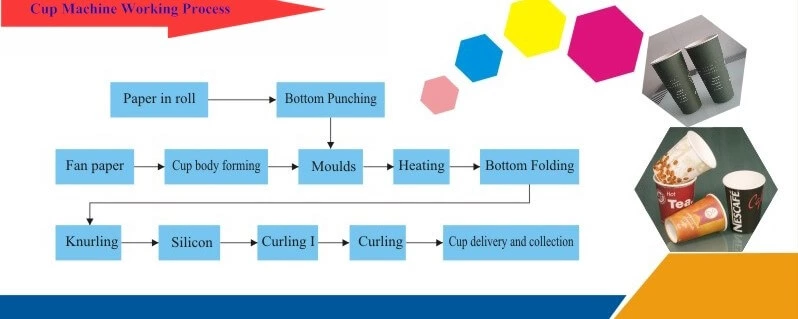

Cup Forming Process

Description

WDF-H22 High Speed Cup Forming Machine is designed to make one & two sides PE coated paper cups for cold and hot drinking cups as well as food containers.

WDF-H22 runs automatically for paper feeding, body sealing, bottom feeding and punching, heating, knurling, top curling, cup discharging and collecting.

Characteristics

1. It is designed with advanced imported cam, which offers high precision indexing and positioning as a result of its good quality and good inertia-resistance capability.

2. PLC control system for the whole cup forming process . Servo control to send bottom paper of cup, deliver bottom when cup tube come, otherwise no bottom delivery.

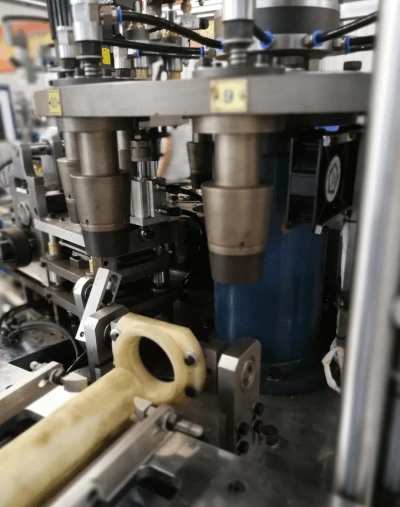

3.Hot air heating device is equipped on cup body and bottom adhesion

step .Cup-bottoms are heated before folding,thus improving heating effect and helping guarantee knurling quality.

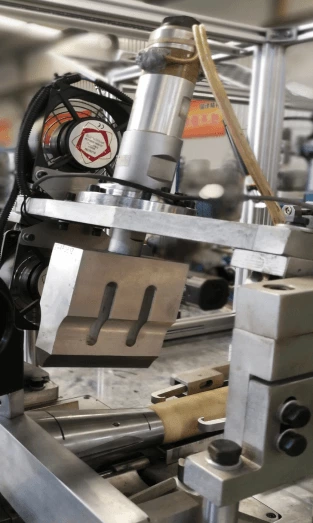

4. Top forming by a curling device and mold. It will go through two steps of curling, to make a perfect cup top.

5. Photoelectric failure-detecting system, offering a high speed and stable operation. The machine will auto-stop working when there is a failure.Thus it can greatly improve operation safety standard and help reduce labor force. It simplifies paper cup forming process.

6. Automatic oil lubrication system, to make machine running fast and simplify routine maintenance of the machine.

7. Automatic cup delivery and collection system with counter.

8. Complete safety guard enclosure with doors and interlock switches

9. It is easy to make cups with different sizes by changing molds.

Technical Data

|

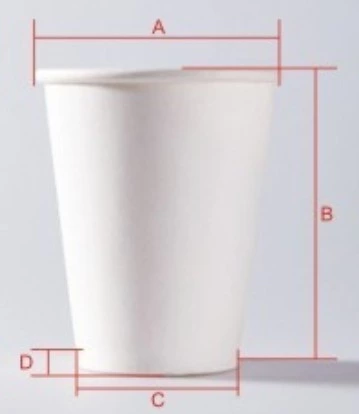

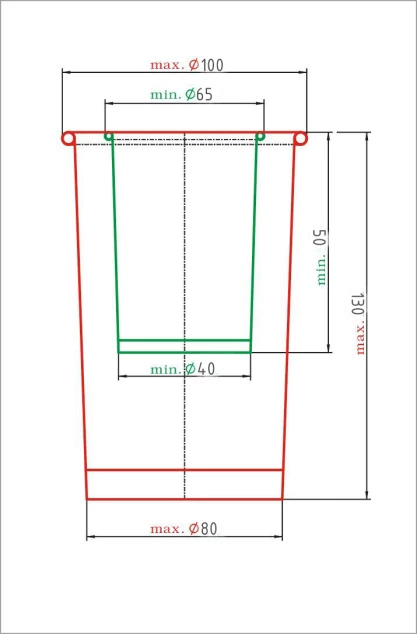

Paper Cup Size |

(A) 65-100mm; (B) 50-130mm; (C) 40-80mm; (D)4.5-10mm |

Production Capacity |

90-120pcs/min |

|

Raw Material |

160-350gsm PE coated paper Aluminized paper |

||

|

Air Consumption |

0.35-0.5m3/min |

Air Source Request |

0.6Mpa |

|

Rated Power |

12KW |

Running Power |

7KW |

|

Power Source |

380V50HZ or other |

Weight |

3600kg |

|

Delivery Time |

40days |

Machine Dimension |

2600 x 1350 x 2000mm |

Finished Product Range:

- Top Diameter: 65 - 100mm

- Bottom Diameter: 40- 80mm

- Total Height: 50 - 130mm

- Other sizes upon request

Machine Details

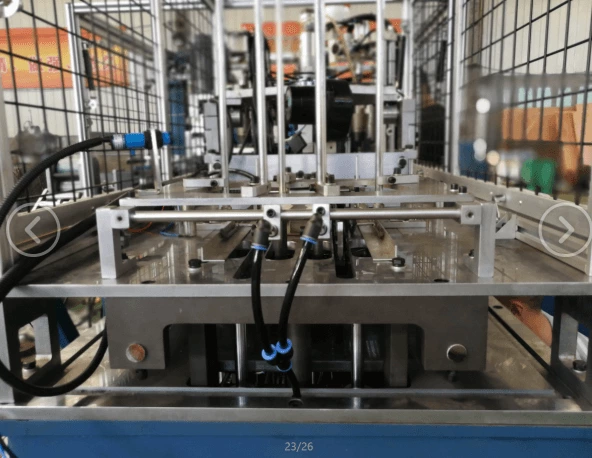

1. TWO TURNPLATE: one plate for 10 cup forming molds, one for cup top curling.

Each plate controlled by each cam, the cam will be much more long life.

And the machine will run steady, the speed will be not lower year by year. For example, during for the first year, the speed is 80-100pcs, even 5 year or 7 year later, the speed will be same.

2. TWO CAM: the machine has two cams. One bigger for main plate, one smaller for the top curling. And the cam is imported from Taiwan, same brand with German Horauf machine.

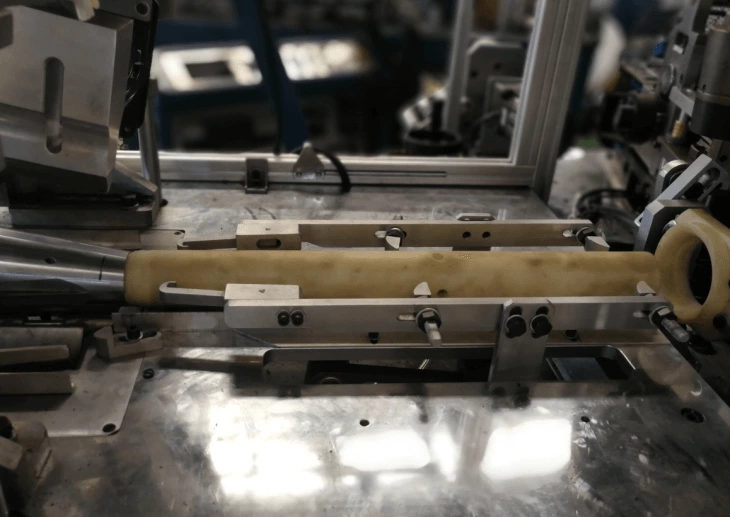

3. PAPE FEEDING AND THE CUP CONE DELIVERY: it has two blower to make sure one paper feeding, will not feeding two or more papers one time. And it has two steps to delivery paper to cup cone sealing mold. And the paper cone delivering mold is long enough to delivery paper cone to main molds. And we use 18K ultrasonic, it’s enough for paper cup or paper bowl machines.

4. MAIN MOLDS: it has 10pcs molds. And all mold material is special mold steel. Will not be broken. And the mold bottom will keep the cup bottom, then paper cone feed to the mold, this make sure the bottom paper good position for the cup, no need adjust , and no need worry about the bottom paper turn over.