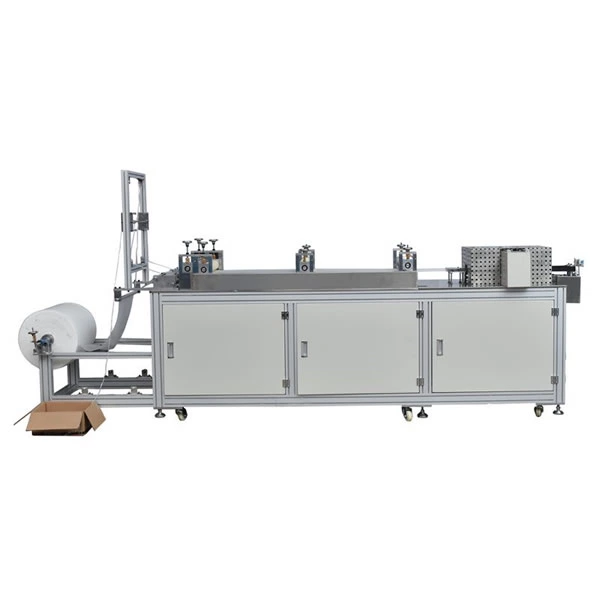

Automatic Mid-Speed Paper Cup Machine

Automatic Mid-Speed Paper Cup Machine

Product Instruction:

WDF-L750 MID-speed paper cup forming machine is a multi station high-speed automatic machine producing both single and double PE coated drink cups,ice cream cups through continuous process of automatic paper feeding,sealing,oil injection,bottom cutting,heating,knurling,curling and stacking.The machine adopting hot air system,PLC control,servo motor driving,full-automatic failure warning,counting,detection,stopping,etc.

Leading technology:

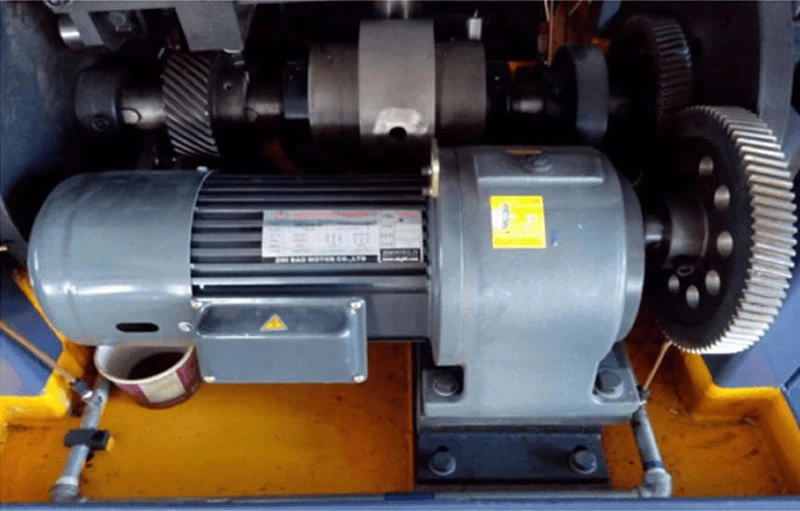

- Adopt open CAM and gear transmission system.machine run stably under high speed operation.

- Using hot air heating system, to keep cups no leaking under high speed.

- The parts are all made of standardized production,strong commonality,swap performance is good,easy to maintenance.

- The automatic lubrication system,closed,can ensure the machine long time continuous high-speed operation.

- Intelligent design,PLC automatic control,automatic fault alarm,count.testing,and stop action.

- The machine is a compact paper cup machine helping clients to save 60% shipment cost.

main technical parameter

| paper request | paperrequest |

| voltage supply | 220V50HZ/380V50HZ or customized |

| cup size | 1.5-9oz |

| speed | 85-90pcs/min |

| general power | 6KW |

| weight | 2000KGS |

| measurement | 2.2*1.15*1.7M |

Machineadvantage:

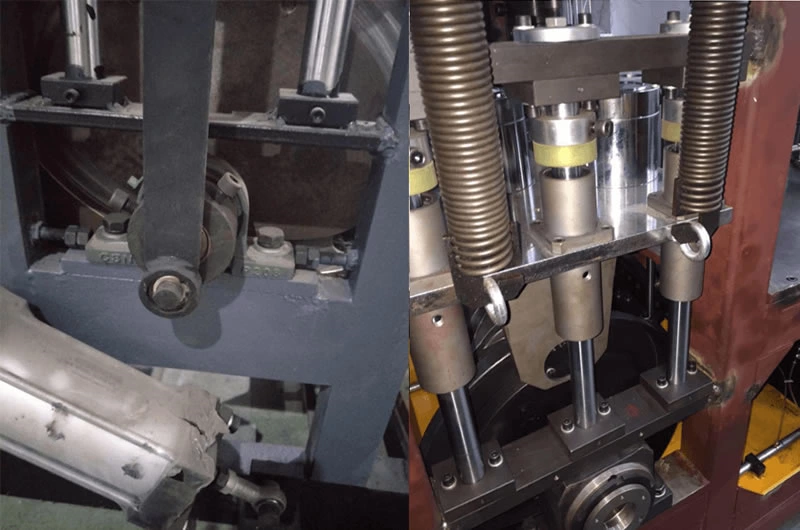

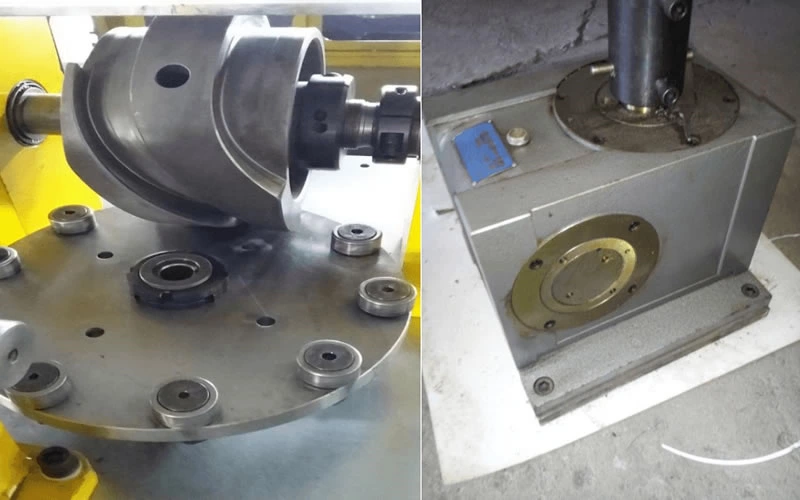

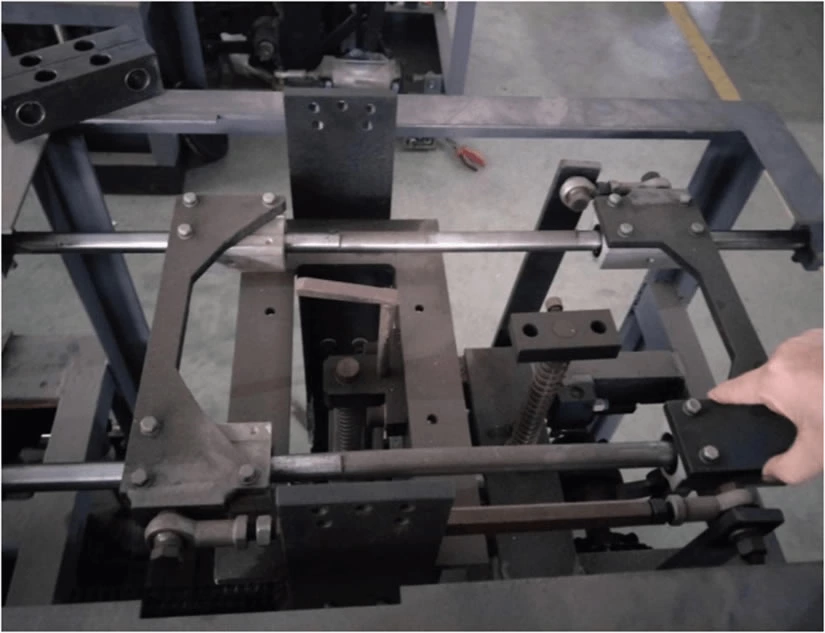

1.Main part uses the Geneva open cam, instead of old dividing box transmission, makes driving more accurate, faster,and more reliable stability

2. Machine bottom is made by CNC machining, shaped in one-piece, the thickness is more than others’ and heavier.It can improve the precision for each part, also help to stable the open cam long timerunning.

3. The panel also to be one piece, better design than old machine.

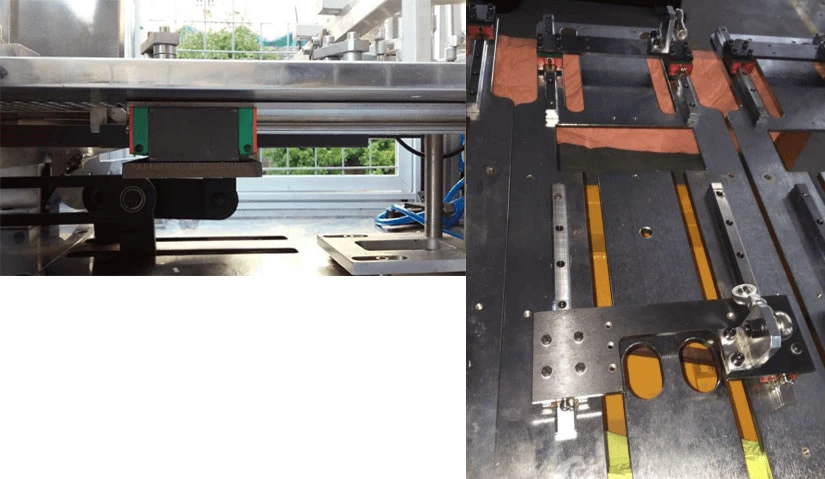

4. The sliding block is imported from Taiwan, instead of the old linear bearing design, this block has a long lifetime, and high precision.

old linear bearing design

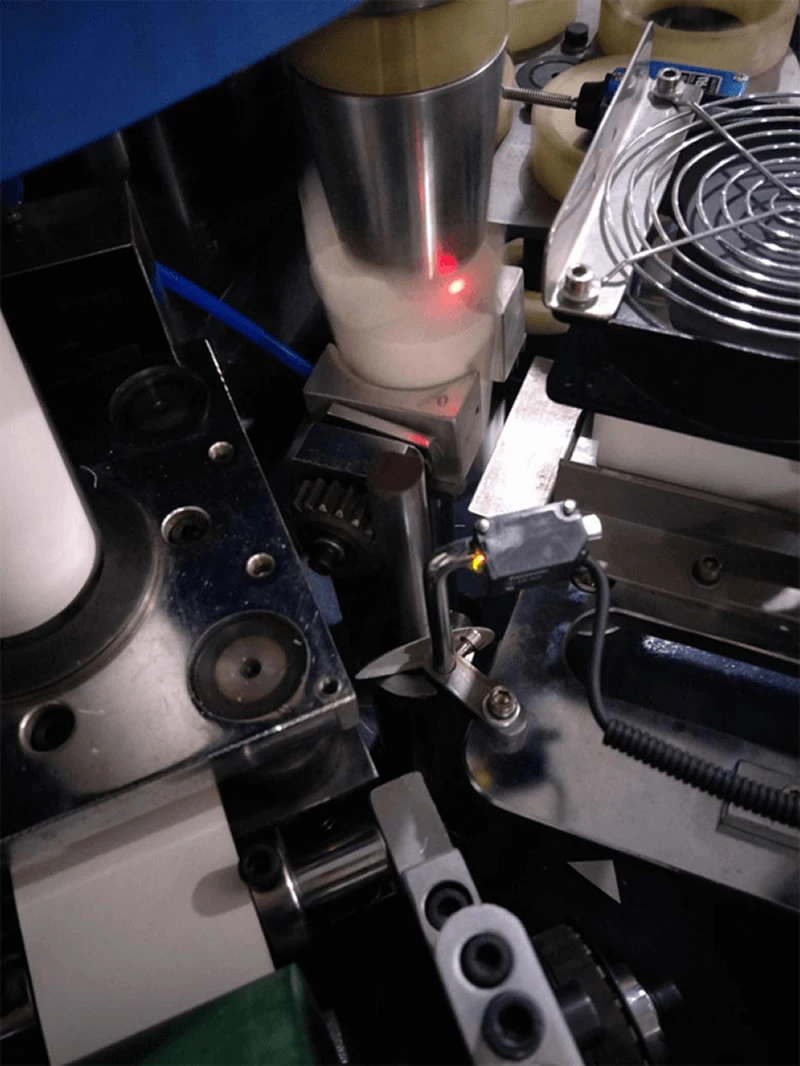

5. Gear robot arm, for taking cup body.

6. The bottom paper feeding is adopted Two channel sending system, first use stepper motor transport, second adopt stepper motor precision feeding, to ensure accuracy and avoid waste. For old design, will have high waste also will produce muchscraps of paper during production.

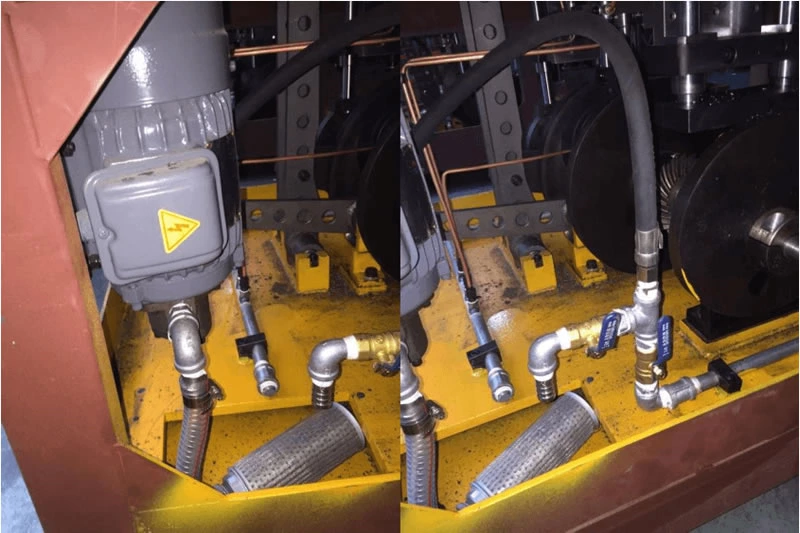

7. This machine has automatic lubrication system, ensure the machine to keep long time running stably. The designof the oil pipe, canlubricate each point more accurately.Wealso add filter screen to keep the lifetimeof oil core. Also this machine has oil pump and two valves, one valve for controlling the oil quantity, one is convenient to change oil.

8. The main motor with brake, making the testing stop positioning, debugging positioning to be higher precision, also to ensure the safety of debugging person.

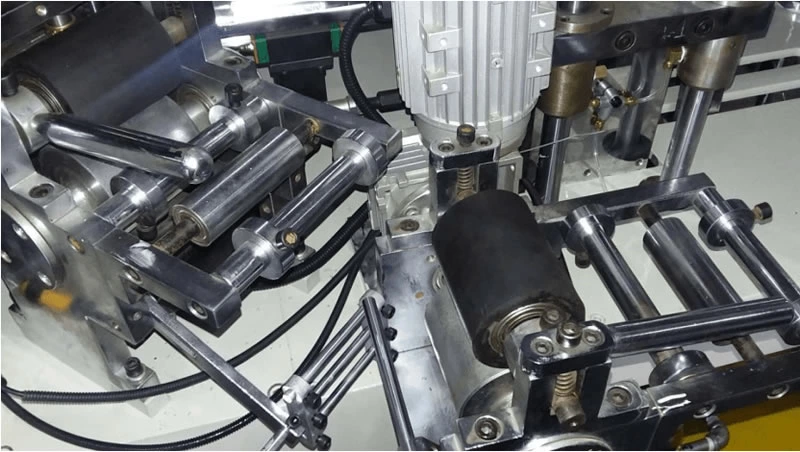

9. New bearing improves the stable running of open cam system, also increase the lifetime and machine speed, old bearing other one use on machine can only support machine to run at low speed. please check below picture. Inside of the bearing sleeve, we have two imported bearing

Old bearing and new bearing